Bullet Train Reverse Engineering Project

Super Steel and L & L Tooling Itasca, Texas

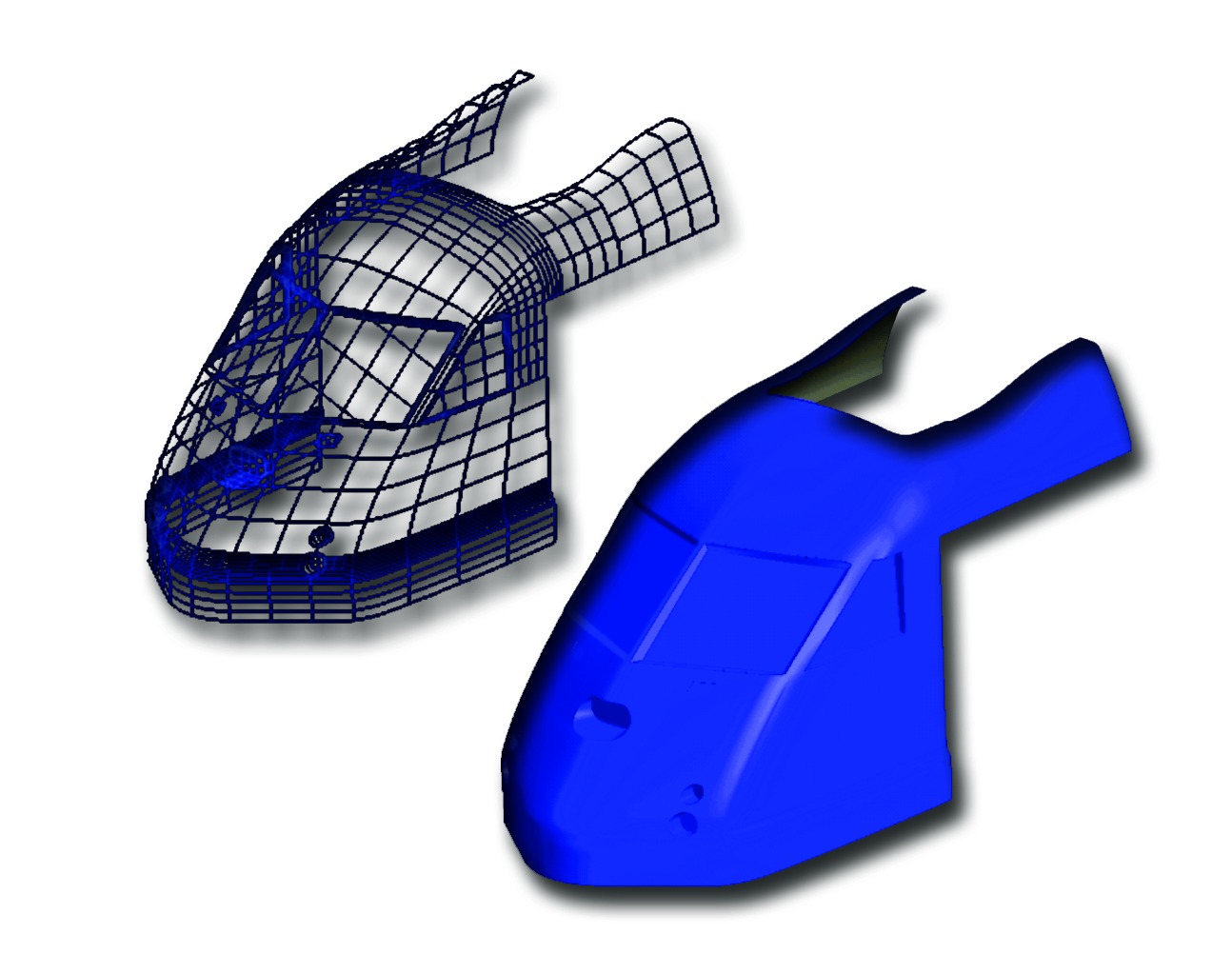

Define geometry of bullet train model master and generate surface models for future design changes

ATT Metrology Solutions was contracted to perform the reverse engineering of an existing model master into a CAD model for Super Steel. The project required the digitizing of the 10-ft. by 8-ft. by 15-ft. model using a laser tracker. ATT Technicians collected nearly 60,000 points on the model master over a two-day period. The data was then imported into Imageware Surfacer software to generate the surfaces from the point cloud data. Surfacing required approximately one week to accomplish. Models were compared to original point cloud data to make sure they were within required customer tolerances.