ATT Metrology is the leading reverse engineering metrology company, actively working with customers to develop engineering models from existing parts or tools, i.e., “reversing” the normal engineering processes.

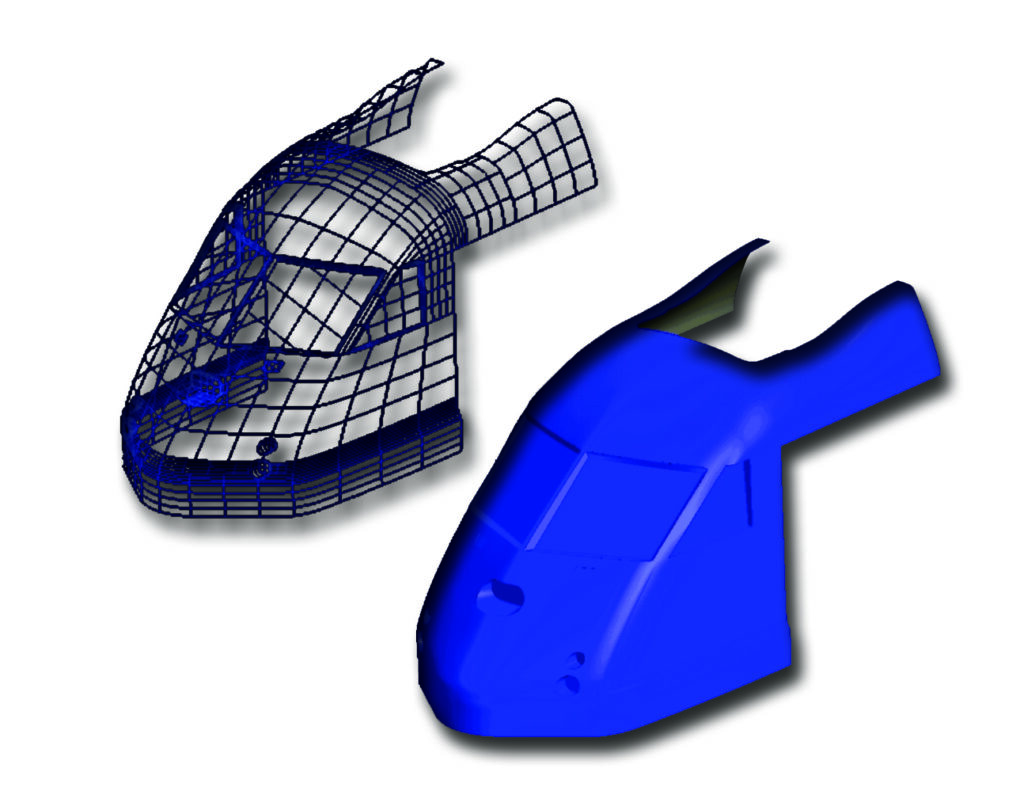

The key to accurate reverse engineering is getting the metrology data collection right. At ATT, we rely on decades of experience to apply the right tools and methods from our portfolio to collect measurement data in the most efficient way possible. This allows us to construct high-precision models in Catia V5, Siemens NX, or SolidWorks from polygonized geometry.

Being one of the most trusted reverse engineering metrology equipment companies, our methods include creating advanced point cloud data collection techniques to optimize the fitting of surfaces to complex shapes and surfaces. We regularly conduct “virtual fits” of existing components prior to the final join step in the manufacturing process to assist our clients in reducing flow time in the fabrication of major assemblies.

Contact us to discuss how our team of metrology and CAD experts can support your reverse engineering metrology needs.